|

Wood |

Neoca Wood is the father of the Neoca brand, it started as a project and slowly became a very nice and original flashlight.

The whole construction process, with its high and lows, was documented in the CPF forum.

I'll post some photos in the next days to show the whole development process.

Very Early Prototypes

First published photo, all the non available parts where modelled in wood

Size comparision with an AA battery

Measuring the prototype, this measure is the same as the final product!!

Failure to make a PCB using a dremel

Introducing The Wooden Skin Concept

First Skinnable prototype

Family shoot

Comparing the size with an AA battery

Its Alive!!! I used a Lambda converter board

Another view

Third Stage Of The Development Process

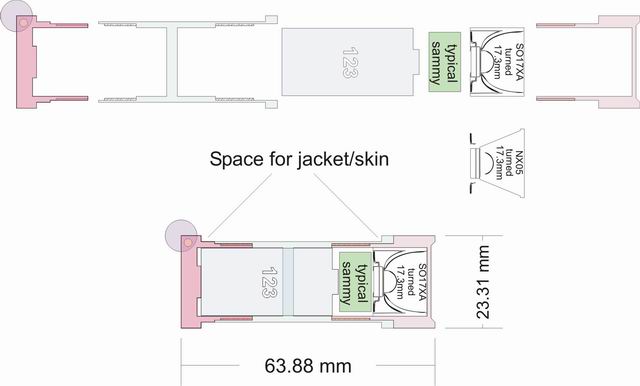

2D Blueprints, these were the first and last, after figuring out that a 3D CAD program was a far better solution, I teached myself how to use it.

First 3D drawing, at this moment the NEOCA brand wasn't introduced yet

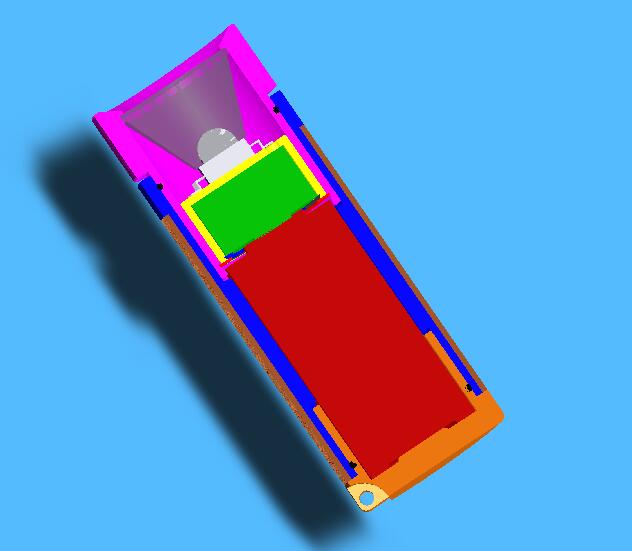

First render that closely resembles the final product

Cut view

Machining The First Prototype

First Machined prototype, still skinless

Another view

The first Neoca skin was made of handpainted grilon, giving it a very nice marbleish look

Another view

The family expanded, first brass unit and wooden skin

Second wooden skin

This is the same skin but shown from different sides

Skins don't resist shocks

Introducing the Quebracho skin

And a new look at the quebracho skin, but after sun tanning. Quebracho when first machined looks whiteish, after a couple of days it turns into a red color that stays the same for loooong time

The 50 units are finally going to be produced, blueprints ready for the shop

Production Finished, assembly has begun

There were made 50 brass units, only 40 brass bodies and only 3 aluminium (later nickel plated) bodies passed the quality test.

Quebracho tans with time, here are the different stages

More nice pictures

Powered by QwikiWiki 1.5.6- www.qwikiwiki.com